MAGFINE

Enabling “free rotor design”

The World’s strongest bonded magnets

MAGFINE is the world’s strongest anisotropic bonded magnet.

Its high freedom of form helps in achieving application performance equivalent to or better than that of neodymium-based sintered magnets in motor actuator manufacturing.

In addition to omission of manufacturing process through integrated injection molding, bonded magnets also have features such as being free of heavy rare earth metals.

With MAGFINE, we are committed to working together with our customers to create the ultimate product.

Strengths of Aichi Steel

-

MAGFINE

MaterialsManufacturing

processResource saving -

Design capabilities

Customer strengths

Applications

Services

Enhancing functionality of application services

-

Miniaturization and weight reduction

-

Higher output

-

Energy saving

The Strength of 3 + 1

3

Strengths ofMAGFINE

-

MaterialsThe world’s strongest bonded magnet

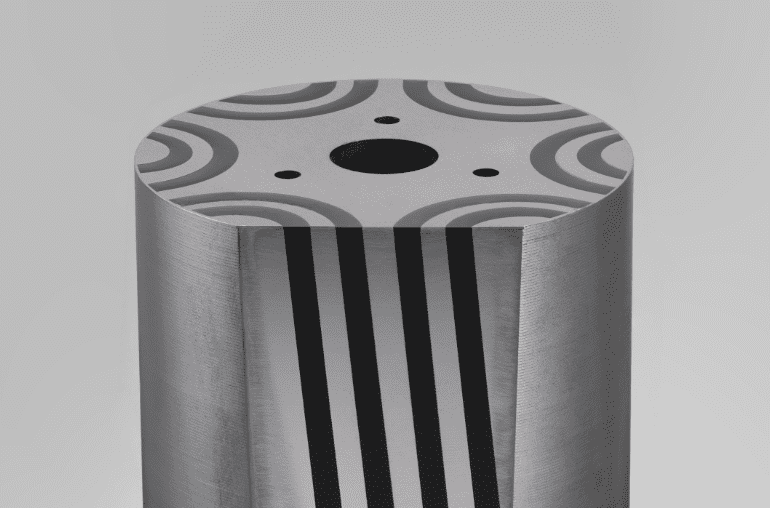

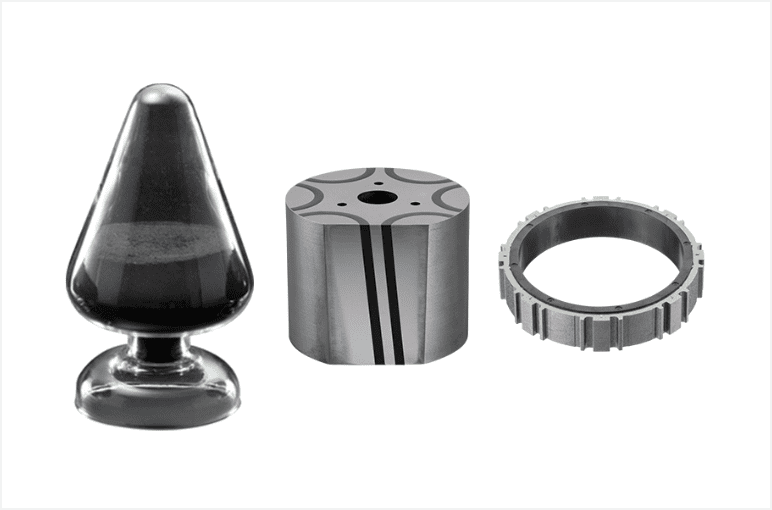

MAGFINE uses anisotropic magnetic powder that has outstanding magnetic properties. It has the world’s strongest magnetic force as an anisotropic Nd-Fe-B bonded magnet. As it is a composite material consisting of magnetic powder and resin, it has immense flexibility and boasts high compatibility with ideal motor designs.

-

Manufacturing processOmission of manufacturing process

MAGFINE can be molded into various forms, and actualizes integrated injection molding by direct mixing during rotor core manufacturing. As a result, processes of cutting machining, assembly bonding, and magnetization which were previously necessary are omitted contributing to reductions in personnel and equipment.

-

Resource savingHeavy rare earth metals

We do not use the rare earth elements Dy and Tb that are subject to significant supply and price fluctuations, and for which environmental pollution during mining is an issue. We also do not use Co, a specific chemical substance that can lead to health issues. In addition to considering environment and health concerns, we have also reduced risks in procuring of resources.

1

Strengths of Aichi Steel

-

Design capabilitiesRotor designing with customers

We have the technology and knowledge to create rotors in collaboration with customers. By leveraging the immense flexibility of MAGFINE with expertise accumulated through numerous achievements in production, we are able to design and manufacture final products tailored to customer wishes.

Development

cases

Examples of achievement through the strengths of 3+1

Products handled

Application cases

Examples of consumer use

-

Electric tool

-

Rechargeable mowing machines

-

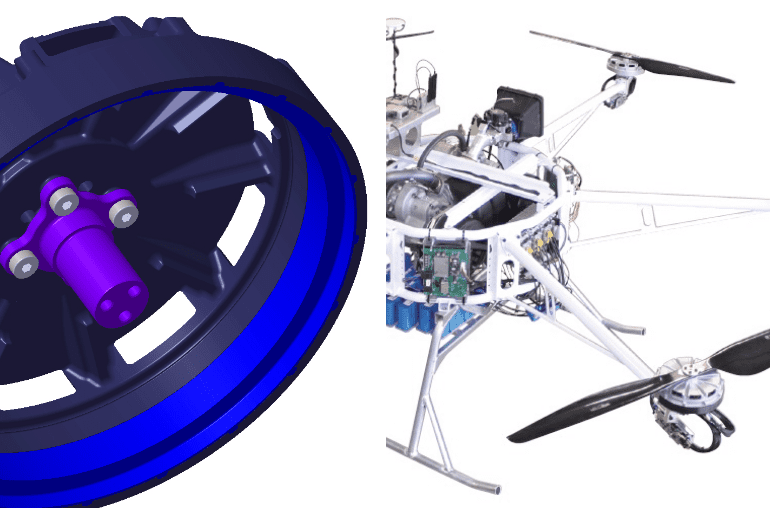

Drone

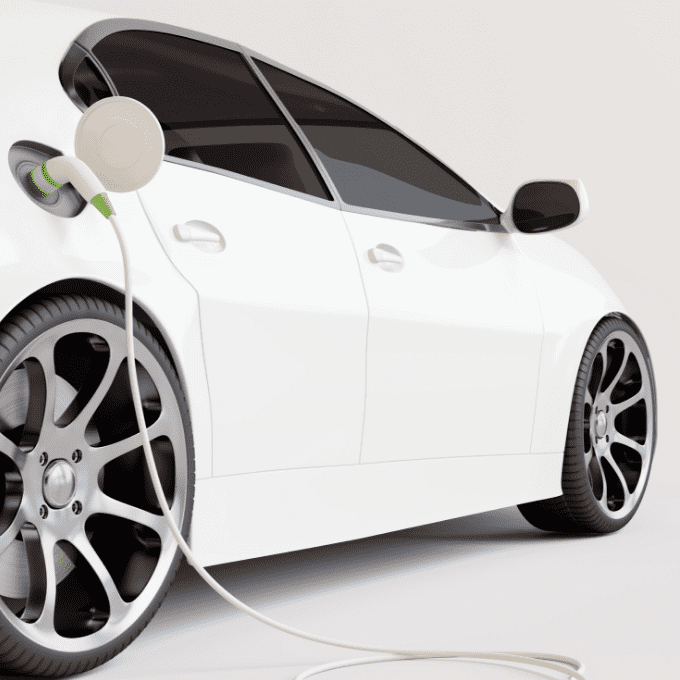

Examples of automotive applications

-

Power seat motor

-

Sunroof

-

Rear wiper

News

- Newly developed corrosion-resistant bonded magnets, samples available from September

- MAGFINE® New Product Sample Sales Begin Significant Improvement in Corrosion resistance of the World’s Strongest Bonded Magn

- Aichi Steel, Tohoku University Successfully Enhance the Performance of Anisotropic Nd-Fe-B Magnetic Powder

- Aichi Steel Develops World's First 34,000RPM, 40% Downsized Electric Axle

- Bolstering the Basis of Magnet Business in China -Conversion of Zhejiang Aichi Mechanical & Electrical Co., Ltd. into a Consolidated Subsidiary-

We have been selected as a 2020 Global Niche Top 100 Company by Ministry of Economy, Trade and industry of Japan

Product inquiries

Phone

Aichi Steel Corporation Smart Company

Magnet Business Team

TEL +81 (52) 603-9286

Internet

Click here to make an inquiry about our products online

About Aichi Steel

Aichi Steel is a steel manufacturer that supports the Toyota Group. The Group has advanced material development capabilities and highly reliable design and production systems established through the development of automobiles. Using these capabilities and systems, the Group develops materials in addition to iron including stainless steel, titanium, and magnetic materials.

The Group’s magnetic materials are used in products that require advanced functionality and designs such as compact sensors and medical devices.