Microalloyed steel

| Supported standards | AICHI

|

|---|---|

| Names of steel types | SVd40 - SVd53, SVd40K,SVdT20 - SVdT40, SVd25BS - SVd35BS, SVd25BM - SVd35BM, SVd38HC, SVd45HT, SVd40ST, SVd15BX |

Features

- These steels are designed to omit the heat treatment of parts produced by direct machining after quenching and tempering of rolled/hot forged parts.

- These steels can be applied to induction hardened parts.

- We provide a wealth of steel type variations.(Please consult with us for specifications not given below)

- We have experience delivering to industries from automotive to construction machinery, industrial equipment and more.

Type of steel/Chemical composition

| Classification | Microstructure | Names of steel types | Main chemical components Representative value (%) | Hot forging | Direct machining | Features | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Other chemical elements | ||||||

|

Basic type |

Ferrite/pearlite type | SVd40K | 0.38 | 0.25 | 0.7 | ≦0.25 | Additive V Addition and adjustment of other chemical elements |

〇 | Strength characteristics equivalent to quenched and tempered carbon steel | |

| SVd40 | 0.40 | 0.25 | 0.7 | ≦0.25 | 〇 | |||||

| SVd43 | 0.43 | 0.25 | 0.9 | ≦0.25 | 〇 | 〇 | ||||

| SVd45 | 0.45 | 0.25 | 0.8 | ≦0.25 | 〇 | 〇 | ||||

| SVd48 | 0.48 | 0.25 | 0.8 | ≦0.25 | 〇 | 〇 | ||||

| SVd50 | 0.50 | 0.25 | 0.8 | ≦0.25 | 〇 | 〇 | ||||

| SVd53 | 0.53 | 0.25 | 0.8 | ≦0.25 | 〇 | 〇 | ||||

| High toughness type | SVdT20 | 0.20 | 0.25 | 1.2 | ≦0.25 | 〇 | Superior strength/toughness balance compared to the basic type based on optimization of the amount of C and Mn | |||

| SVdT25 | 0.25 | 0.25 | 1.2 | 0.3 | 〇 | |||||

| SVdT30 | 0.30 | 0.25 | 1.2 | 0.3 | 〇 | 〇 | ||||

| SVdT38 | 0.38 | 0.25 | 1.2 | 0.3 | 〇 | 〇 | ||||

| SVdT40 | 0.40 | 0.25 | 1.2 | 0.3 | 〇 | 〇 | ||||

| Bainite type | SVd25BS | 0.25 | 0.25 | 1.5 | 0.5 | 〇 | Superior toughness compared to ferrite and pearlite types | |||

| SVd30BS | 0.30 | 0.25 | 1.5 | 0.5 | 〇 | |||||

| SVd35BS | 0.35 | 0.25 | 1.5 | 0.5 | 〇 | |||||

| SVd25BM | 0.25 | 0.25 | 1.5 | 0.5 | 〇 | |||||

| SVd30BM | 0.30 | 0.25 | 1.5 | 0.5 | 〇 | |||||

| SVd35BM | 0.35 | 0.25 | 1.5 | 0.5 | 〇 | |||||

| High strength type | Ferrite/pearlite type | SVd38HC | 0.38 | 0.25 | 0.7 | 0.2 | 〇 | High fatigue strength | ||

| SVd45HT | 0.45 | 0.25 | 1.2 | ≦0.25 | 〇 | 〇 | ||||

| SVd40ST | 0.40 | 0.25 | 1.5 | 0.25 | 〇 | |||||

| Bainite type | SVd15BX | 0.13 | 0.25 | 2.2 | 1.0 | 〇 | High yield ratio through aging treatment with excellent toughness | |||

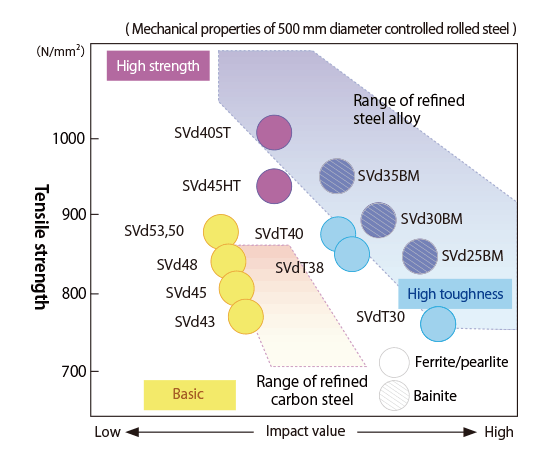

1. Positioning of strength/toughness of microalloyed steel for direct machining

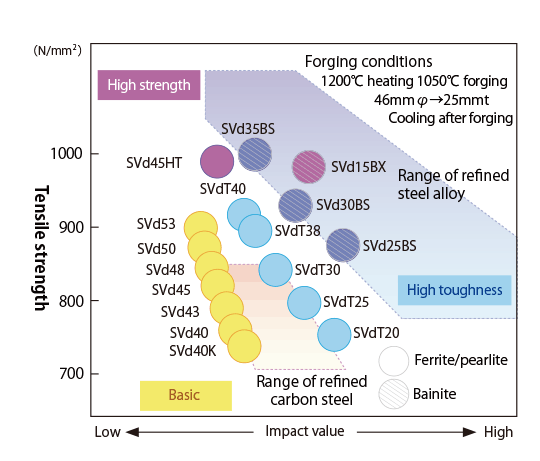

2. Positioning of strength/toughness of microalloyed steel for hot forging

Advantages

Microalloyed steels have specific characteristics as hot-rolled /hot-forged steel and possess the following advantages:

- (1)

- CO2 emissions can be reduced by omitting heat treatment processes.

- (2)

- Heat treatment (quenching and tempering) process cost can be reduced.

- (3)

- Quenching torsion can be reduced and higher dimensional accuracy is expected. (Abbreviation or simplification of straightening processes)

- (4)

- Takt time and amount of unfinished inventory can be reduced.

Major applications

- Automotive/Truck:

- Crank shafts, accelerator shafts, torque tubes

- Construction machinery:

- CVJ intermediate shafts, hydraulic cylinders, knuckles, torque shafts, rear shafts, piston rods, rollers, etc.

Product inquiries

Phone

AICHI STEEL Corporation

Sales and Planning Division

TEL +81 (52) 603-9362

Internet

Please complete any inquiries from the below.

- Please understand that we may not be able to accept specific orders depending on the circumstances even for information given on this website. Feel free to contact us for the latest information.

Note that information given on this website is subject to change without notice.