Product

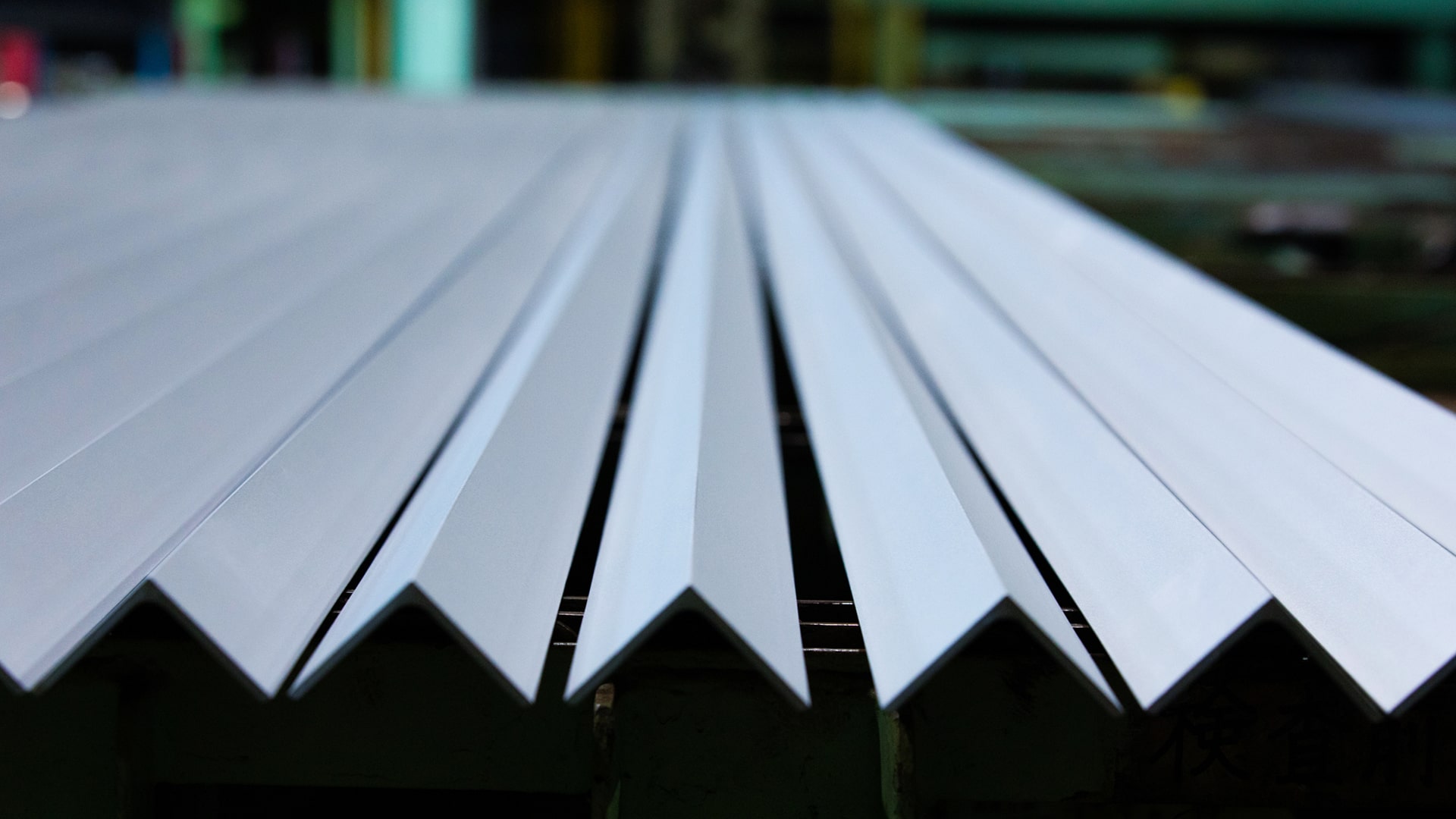

Kariya Plant Products

Stainless steel is a type of steel made from iron that contains at least 11% chromium.

It has excellent corrosion resistance, design characteristics, high-temperature strength, low-temperature toughness,

non-magnetism, resistance to hydrogen gas embrittlement, and other properties,

and is used in a wide range of fields including construction, civil engineering, water treatment, and energy.

In addition, stainless steel is easily recycled, making it an environmentally friendly recyclable resource.

Stainless Steel

Stainless Steel

Where can you find stainless steel ?

-

Corrosion resistance

Photo courtesy of SS. Inc.

Vertical greening cylinders

Photo courtesy of SS. Inc.

Vertical greening cylinders

at Aichi International Convention & Exhibition Center - Design characteristics

Interior stairs in Aichi Steel Administration Building

Interior stairs in Aichi Steel Administration Building - High-temperature strength

Tunnel fire extinguisher mounting fittings

Tunnel fire extinguisher mounting fittings

on the Shuto Expressway Shinjuku Route -

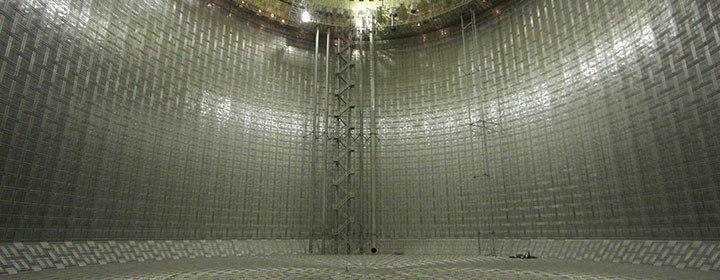

Low ductility in low temperatures

Photo courtesy of Toho Gas Co., Ltd.

Internal deck and stairs inside LNG tank

Photo courtesy of Toho Gas Co., Ltd.

Internal deck and stairs inside LNG tank

- Non-magnetic

Overall frame

Overall frame

of the Kyushu University Research Institute

of Superconductor Science and Systems - Resistance to hydrogen embrittlement

Receptacle on the MIRAI fuel cell vehicle

Receptacle on the MIRAI fuel cell vehicle

Main Points of the Stainless Steel Business

- Aichi Steel Holds Top Share in Japanese Production of

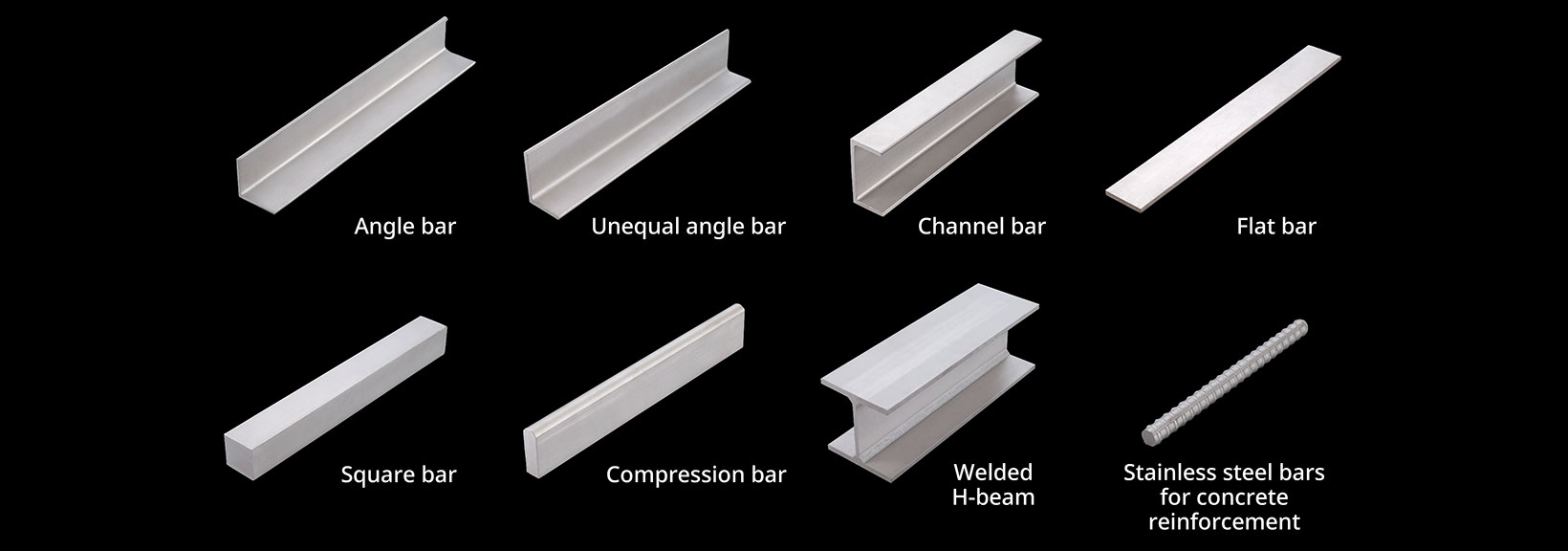

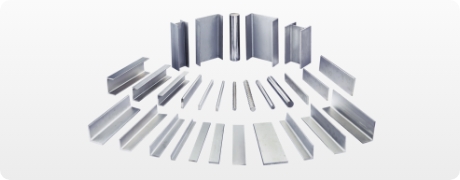

Stainless Steel Shapes and Flat Steel - Since 1958, when we started producing Japan’s first hot-rolled stainless angle bar at the Kariya Plant, where we were founded, we have provided the market with over 4,000 products of different shapes, dimensions, and steel types.

Aichi Steel’s share of domestic production of flat and shaped stainless steel products exceeds 70%. -

- Enhanced Stainless Steel

Building Structure Engineering Functions - Aichi Steel established stainless steel structural engineering functions in 1996 and is involved in all process from design cooperation with general contractors and others to plant production of materials and components and onsite installation and civil engineering work.

In 2019, Aiko Corporation, a subsidiary, constructed the Kinuura No. 2 Plant, expanding plant manufacturing capabilities. -

Examples of production

Examples of production Examples of production

Examples of production

- Diverse Technical Capabilities Support the

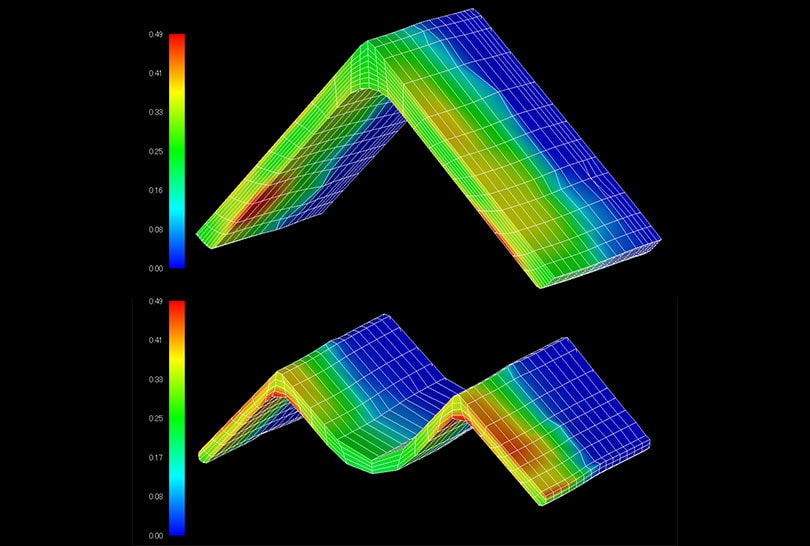

Stainless Steel Product Portfolio - We use simulation technologies that employ rolling FEM analysis to develop practical machines for an extensive range of steel shapes based on high-precision and optimized investigations of designs.

In conjunction with the spread of hydrogen energy, we are developing material evaluation and testing equipment that can operate under high-pressure hydrogen environments, accelerating the development of stainless steels for high-pressure hydrogen, and we are working to enhance their reliability. -

Results of a rolling FEM analytics simulation

Results of a rolling FEM analytics simulation Rotating bending fatigue test apparatus

Rotating bending fatigue test apparatus

corresponding to high-pressure

hydrogen environment (World’s First)