Product

Chita Plant Products

Specialty steel is iron to which special metals (ferroalloys) have been added.

Depending on the ferroalloys that are added,

we can create specialty steels with various properties such as being harder, tougher, more heat resistant, or more machinable than general steel.

Aichi Steel makes use of this characteristic to develop specialty steels optimized according to customer wishes.

Specialty steel is used in automobile components that are crucial for safety and must operate under demanding environments

such as the engine and suspension, taking advantage of its strength.

Specialty Steel

Specialty Steel

Where can you find specialty steel ?

Automobiles

Automobiles Machine tools and construction equipment

Machine tools and construction equipment

Main Points of the Specialty Steel Business

- Resource Recycling Business

Uses Steel Scrap as a Raw Material - In our manufacturing business, we use steel scrap generated during automobile body processing and from end-of-life vehicles as a raw material.

As a recycling-oriented company, we are contributing to the preservation of the global environment through our business by recycling steel resources. -

Scrapyard

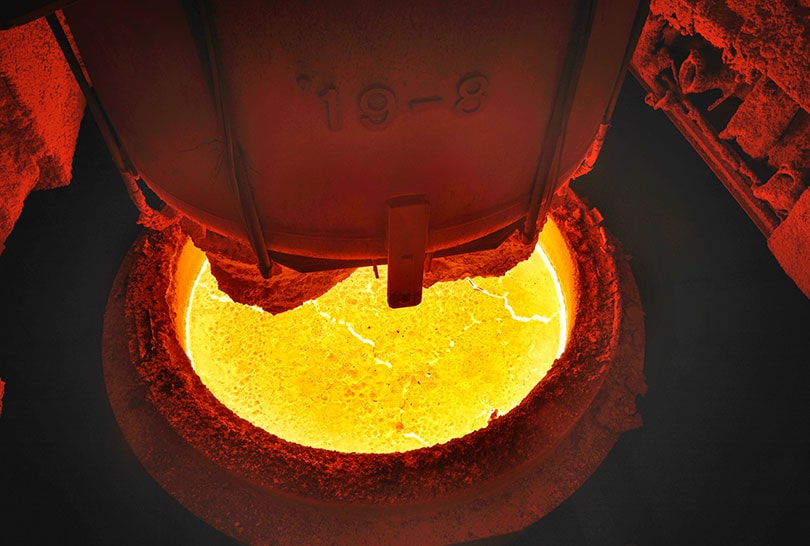

Scrapyard Electric furnace

Electric furnace

- First Use in Japan of Waste Heat

from an Electric Furnace to Convert Steam Energy - We introduced a mechanism that passes waste heat from electric furnaces through a boiler to recover the heat in the form of steam energy and effectively uses that energy in vacuum degassing equipment and other steel manufacturing equipment.

This is the first case of such use of waste heat in the Japanese electric furnace industry. This system enables us to cut CO₂ emissions by the equivalent of approximately 4,200 tons annually.

This innovative system is contributing to carbon neutrality. - Initiatives

to Achieve

Carbon

Neutrality -

Exhaust heat recovery

Exhaust heat recovery Vacuum degassing unit

Vacuum degassing unit

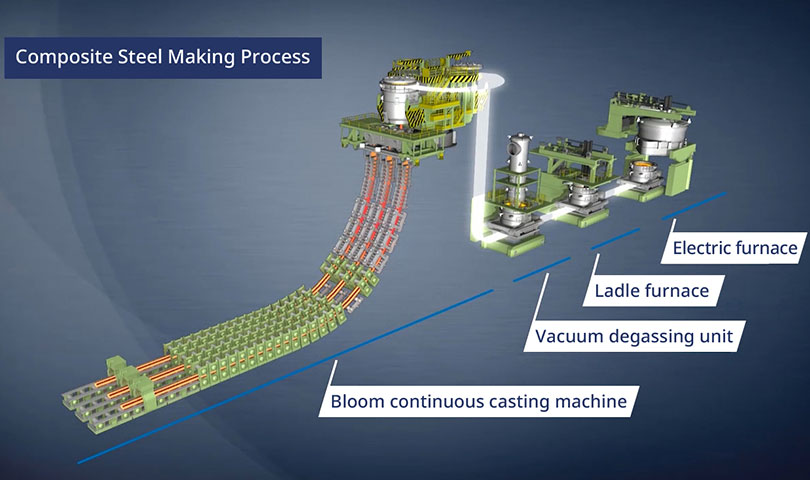

- Composite Steel Making Process

Used to Achieve Number One Production

on Single Bar Rolling Line in Japan

and Top Domestic Share for Hot-Rolled Steel Bars

(Low-Alloyed Steels for Machine Structural Use) - Aichi Steel began operation of the world’s first composite steel making process, which links multiple steel making devices in a series, in 1982.

To raise high competitiveness in the areas of quality, price, and delivery time, we have continuously developed facilities since then.

The steel blooms manufactured using this process pass through rolling and inspection processes and are supplied to customers in the form of high-quality specialty steel bars. -

Diagram of the composite steel making process

Diagram of the composite steel making process Cooling bed of the rolling plant

Cooling bed of the rolling plant