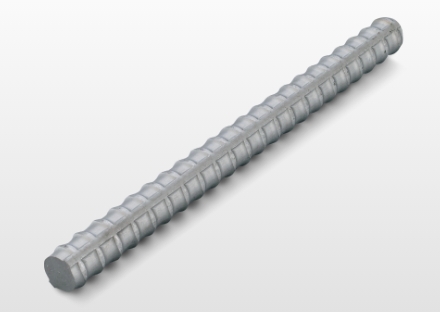

Stainless steel bars for concrete reinforcement

| Supported standards | JIS G4322 Stainless steel bars for concrete reinforcement |

|---|---|

| Type code | SUS304-SD, SUS410-SD |

JIS products (JIS G 4322)

Features

- Austenite stainless steel reinforcement bars made from SUS304-SD have excellent durability not only in concrete but also in outdoor environment to salt damage, and additionally are non-magnetic.

- Ferrite stainless steel reinforcement bars made from SUS410-SD have excellent durability in the material itself that can replace steel reinforcement bars with zinc coating or epoxy resin coatings.

Types

- Contact our sales people for types or strength categories other than those given above.

| Type code | Equivalent steel | Strength category | Dimensions | Shape | Length |

|---|---|---|---|---|---|

| JIS G 4322 SUS304-SD |

SUS304 | 295B | D10 to D38 | Ridged (knotted) | 4.0 to 6.0m Tolerance +40mm−0mm |

| SIS304N2 | 345 | ||||

| 390 | |||||

| JIS G 4322 SUS410-SD |

SUS410L | 295A | |||

| 345 |

Chemical components

(%)

| Equivalent steel | C | Si | Mn | P | S | Ni | Cr | N | Nb |

|---|---|---|---|---|---|---|---|---|---|

| SUS304 | 0.08 or less |

1.00 or less |

2.00 or less |

0.045 or less |

0.030 or less |

8.00 to 10.50 |

18.00 to 20.00 |

- | - |

| SUS304N2 | 0.08 or less |

1.00 or less |

2.50 or less |

0.045 or less |

0.030 or less |

7.50 to 10.50 |

18.00 to 20.00 |

0.15 to 0.30 |

0.15 or less |

| SUS410L | 0.030 or less |

1.00 or less |

1.00 or less |

0.040 or less |

0.030 or less |

0.60 or less |

11.00 to 13.50 |

- | - |

Mechanical properties

| Type code | Strength category | 0.2% yield strength (N/mm2 ) |

Tensile strength (N/mm2 ) |

Elongation (%) | Bending |

|---|---|---|---|---|---|

| JIS G 4322 SUS304-SD |

295B | 295 to 390 | 440 or more | D22 or less to 16 or more D25 or less to 17 or more |

Bends 180° without cracks |

| 345 | 345 to 440 | 490 or more | D22 or less to 18 or more D25 or less to 19 or more |

Bends 180° without cracks | |

| 390 | 390 to 510 | 560 or more | D22 or less to 16 or more D25 or less to 17 or more |

Bends 180° without cracks | |

| JIS G 4322 SUS410-SD |

295A | 295 or more | 440 to 600 | D22 or less to 16 or more D25 or less to 17 or more |

Bends 180° without cracks |

| 345 | 345 to 440 | 490 or more | D22 or less to 18 or more D25 or less to 19 or more |

Bends 180° without cracks |

Dimensions, weight and tolerances for bumps

| Name | Nominal diameter (mm) |

Nominal perimeter (cm) |

Nominal cross section area (cm²) |

Maximum average gap of ridges (mm) |

Height of ridges | Maximum value of total of gaps between ridges (mm) |

Minimum angle of ridge to axis (°) |

Unit mass (kg/m) |

||

|---|---|---|---|---|---|---|---|---|---|---|

| Minimum value (mm) |

Minimum value (mm) |

SUS304-SD | SUS410-SD | |||||||

| D10 | 9.53 | 3.0 | 0.7133 | 6.7 | 0.4 | 0.8 | 7.5 | 45 | 0.566 | 0.553 |

| D13 | 12.7 | 4.0 | 1.267 | 8.9 | 0.5 | 1.0 | 10.0 | 1.00 | 0.982 | |

| D16 | 15.9 | 5.0 | 1.986 | 11.1 | 0.7 | 1.4 | 12.5 | 1.57 | 1.54 | |

| D19 | 19.1 | 6.0 | 2.865 | 13.4 | 1.0 | 2.0 | 15.0 | 2.27 | 2.22 | |

| D22 | 22.2 | 7.0 | 3.871 | 15.5 | 1.1 | 2.2 | 17.5 | 3.07 | 3.00 | |

| D25 | 25.4 | 8.0 | 5.067 | 17.8 | 1.3 | 2.6 | 20.0 | 4.02 | 3.93 | |

| D29 | 28.6 | 9.0 | 6.424 | 20.0 | 1.4 | 2.8 | 22.5 | 5.09 | 4.98 | |

| D32 | 31.8 | 10.0 | 7.942 | 22.3 | 1.6 | 3.2 | 25.0 | 6.30 | 6.16 | |

| D35 | 34.9 | 11.0 | 9.566 | 24.4 | 1.7 | 3.4 | 27.5 | 7.59 | 7.41 | |

| D38 | 38.1 | 12.0 | 11.40 | 26.7 | 1.9 | 3.8 | 30.0 | 9.04 | 8.84 | |

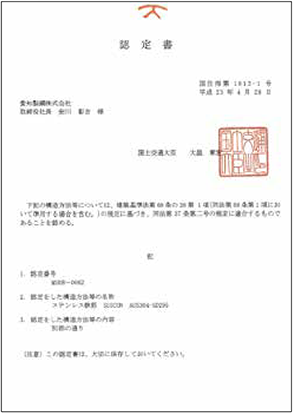

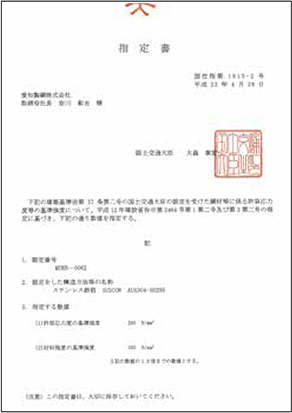

Minister of Land, Infrastructure, Transport and Tourism Certified Product

Features

These stainless steel reinforcing bars, which have received certification from the Minister of Land, Infrastructure, Transport and Tourism as complying with Article 37-2 of the Building Standards Act, are characterized by excellent durability and their non-magnetic properties.

They are used in all or part of building frames where non-magnetic properties are needed such as shrines, temples, and cultural assets that require durability over long periods.

Types

| Type code | Equivalent steel | Strength category | Dimensions | Shape | Standard strength F value |

|---|---|---|---|---|---|

| AUS304-SD295 | SUS304 | 295B | D10 to D38 | Ridged (knotted) | 295N/mm2 |

Chemical components

Based on SUS304 (JIS G 4322)

Mechanical properties

| Type code | Strength category | 0.2% yield strength (N/mm2 ) | Tensile strength (N/mm2 ) | Yield rate | Elongation (%) | Bending |

|---|---|---|---|---|---|---|

| AUS304-SD295 | 295B | 295 to 390 | 440 or more | 60% or less | 40 or more | Bends 180° without cracks |

Dimensions, weight and tolerances for bumps

Based on JIS

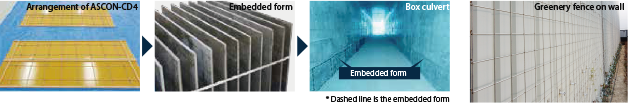

Small diameter stainless steel reinforcing bar ASCON-CD4·CD6

Features

The chemical composition of these small diameter stainless steel reinforcing bars is based on SUS304 under the JIS G 4308 standard, and the strength are at levels that satisfy JIS G 3532 (iron wire) for the welded steel wire and wire for the reinforcement of concrete, SMW-I. They are non-magnetic and have excellent high-strength durability. Small diameter stainless steel rods are cold-reduced to form gap with ridges.

The reinforcing bars are used as reinforcing materials for thin concrete panels (such as buried formworks) and other applications, and are also used in green panels (for green walls and the like) by taking advantage of the thin diameter and knotty shape, which vining plants can easily wrap around.

Product specifications

| Type of steel | Name | Nominal diameter (mm) | Nominal cross section area (cm2) | Yield strength (MPa) | Tensile strength (MPa) |

|---|---|---|---|---|---|

| SUS304 equivalent | CD4 | 4.0 | 0.126 | 440 or more | 540 or more |

| CD6 | 6.0 | 0.283 |

- Shape and mechanical properties conform to JIS G 3532 (iron wire, SWN-I)

Embedded forms reinforced with ASCON-D4

Technical data

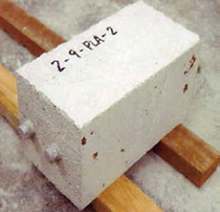

Corrosion resistance in concrete (Reference photograph)

- Chloride ion concentration: 9.0, 15.0kg/m3

- Cement type: Normal Portland cement

- Water-cement ratio: 60%

- Trial reinforcement rods (D13): SUS304 reinforcement rods, SUS410L reinforcements rods, epoxy coated reinforcement rods, zinc coated reinforcement rods, normal reinforcement rods

- Trial method: Various kinds of reinforcement rod are embedded in concrete with chlorine content and then subjected to 770 days of repeating dry for 4 days, wet for 3 days each cycle.

| Type | Chloride ion concentration 9 kg/m3 | Chloride ion concentration 15 kg/m3 |

|---|---|---|

| SUS304 steel rebar |  |

|

| SUS410L steel rebar |  |

|

| Epoxy coated rebar |  |

|

| Zinc coated steel rebar |  |

|

| Normal steel rebar |  |

|

Magnet permeability (reference values)

- Trial reinforcement rods (D16): SUS304 reinforcement rods, SUS304N2 reinforcement rods

- Bending radius: 2.5d

- Bending angle: 180 degrees

Adhesion strength (reference value)

- Test standard: Construction testing center standard: JSTM C 2101

- Cement type: Normal Portland cement

- Water-cement ratio: 69%

- Trial reinforcement rods (D19): SUS304 reinforcement rods, SUS304N2 reinforcement rods, SUS410L reinforcement rods, normal reinforcement rods

| Type | Maximum adhesion stress (N/mm2) |

Rate of maximum adhesion stress for normal steel rebar (%) |

|---|---|---|

| SUS304 steel rebar | 14.1 | 90 |

| SUS304N2 steel rebar | 14.9 | 96 |

| SUS410L steel rebar | 15.0 | 96 |

| Normal steel rebar | 15.6 | - |

Comparison between stainless steel reinforcement rods and epoxy coated reinforcement rods (from design guidelines)

| SUS304-SD steel rebar | SUS410-SD steel rebar | Epoxy coated rebar | |

|---|---|---|---|

| Corrosion limit chloride ion concentration | 15kg/m3 | 9kg/m3 | 1.2kg/m3 *1 |

| Cracking width limit value for concrete steel corrosion | 0.5mm | Smaller of 0.005 c or 0.5 mm | 0.0055c *2 |

| Concreate adhesion strength | Normal steel rebar and equivalent | Normal steel rebar and equivalent | 85% of normal steel rebar |

| During installation and repair of damage from bending | Repair not necessary | Repair not necessary | Touch up repair needed |

| Repair of end surface at cut | Repair not necessary | Repair not necessary | Touch up repair needed |

| Joint | Welding joint and stud joint cannot be used in general | Welding joint and stud joint cannot be used in general | Gas stud joint possible but requires removal of coating for stud joint end surface |

| Magnetic | Non-magnetic | Strong magnetic | Strong magnetic |

- Chloride ion concentration in epoxy coating nearest steel material

- c indicates cover (mm)

Standards

- Japan Industrial Standards: JIS G4322 Stainless steel bars for concrete reinforcement

- Design guidelines (civil engineering): Concrete library 3130 Design Guidelines for Concrete Structures using Stainless Steel Reinforcement Rods (draft)

Minister of Land, Infrastructure, Transport and Tourism Certified AUS304-SD295 Certification and Designation

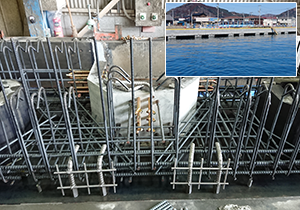

Applications

| Application | Saiwaicho wharf core reinforcement |

|---|---|

| Field | Civil engineering |

| Shape | Steel reinforcement |

| Type of steel | SUS304-SD390 |

| Reason | Corrosion resistance |

| Application | Utakokakyo expansion joint transfer unit |

|---|---|

| Field | Civil engineering |

| Shape | Steel reinforcement |

| Type of steel | SUS304-SD390 |

| Reason | Corrosion resistance |

| Application | The insert used for the installation of electricity cable racks inside the shield tunnel |

|---|---|

| Field | Civil engineering |

| Shape | Steel reinforcement |

| Type of steel | SUS304-SD295B |

| Reason | Corrosion resistance |

| Application | An embedded -type water stoppage joint "Keep dry E" |

|---|---|

| Field | Civil engineering |

| Shape | Steel reinforcement |

| Type of steel | SUS304-SD295B |

| Reason | Corrosion resistance |

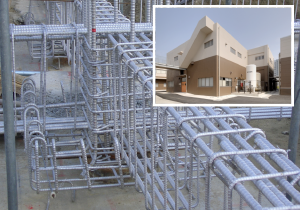

| Application | Okinawa Institute of Science and Technology Graduate University Research Building Skeleton |

|---|---|

| Field | Building construction |

| Shape | Steel reinforcement |

| Type of steel | SUS304-SD295B, SUS304-SD390 |

| Reason | Non-magnetic |

| Application | Important Cultural Asset Osamu Dazai Memorial Museum Brick wall seismic reinforcement |

|---|---|

| Field | Building construction |

| Shape | Steel reinforcement |

| Type of steel | SUS304-SD295B |

| Reason | Corrosion resistance |

| Application | Aomori Museum of Art covering steel |

|---|---|

| Field | Building construction |

| Shape | Steel reinforcement |

| Type of steel | SUS304-SD295B |

| Reason | Corrosion resistance |

| Application | Kyushu University Research Institute of Superconductor Science and Systems complete skeleton |

|---|---|

| Field | Building construction |

| Shape | Steel reinforcement |

| Type of steel | SUS304-SD295B, SUS304-SD390 |

| Reason | Non-magnetic |

| Application | Chuo Expressway Ozawa River bridge PC floor joint |

|---|---|

| Field | Civil engineering |

| Shape | Steel reinforcement |

| Type of steel | SUS410-SD345 |

| Reason | Corrosion resistance |

| Application | Irabu Bridge paving reinforcements |

|---|---|

| Field | Civil engineering |

| Shape | Steel reinforcement |

| Type of steel | SUS304-SD295B |

| Reason | Corrosion resistance |

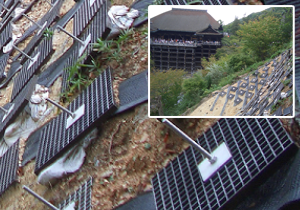

| Application | National Treasure Kiyomizudera lock bolts |

|---|---|

| Field | Civil engineering |

| Shape | Steel reinforcement |

| Type of steel | SUS304-SD390 |

| Reason | Corrosion resistance |

| Application | San-en Nanshin Expressway Wall rail V-cut ground reinforcement girders |

|---|---|

| Field | Civil engineering |

| Shape | Steel reinforcement |

| Type of steel | SUS410-SD345 |

| Reason | Corrosion resistance |

| Application | National Route 153 primary culvert Wall rail paving steel reinforcement |

|---|---|

| Field | Civil engineering |

| Shape | Steel reinforcement |

| Type of steel | SUS410-SD345 |

| Reason | Corrosion resistance |

| Application | Okinawa Prefecture Water Purification Plant fence Concrete pillars |

|---|---|

| Field | Civil engineering |

| Shape | Steel reinforcement |

| Type of steel | SUS410-SD345 |

| Reason | Corrosion resistance |

Product inquiries

Phone

AICHI STEEL Corporation

Sales and Planning Division

TEL +81 (52) 603-9362

Internet

Please complete any inquiries from the below.

- Please understand that we may not be able to accept specific orders depending on the circumstances even for information given on this website. Feel free to contact us for the latest information.

Note that information given on this website is subject to change without notice.