Advanced Evaluation Technology

Testing machine under high-pressure hydrogen environment

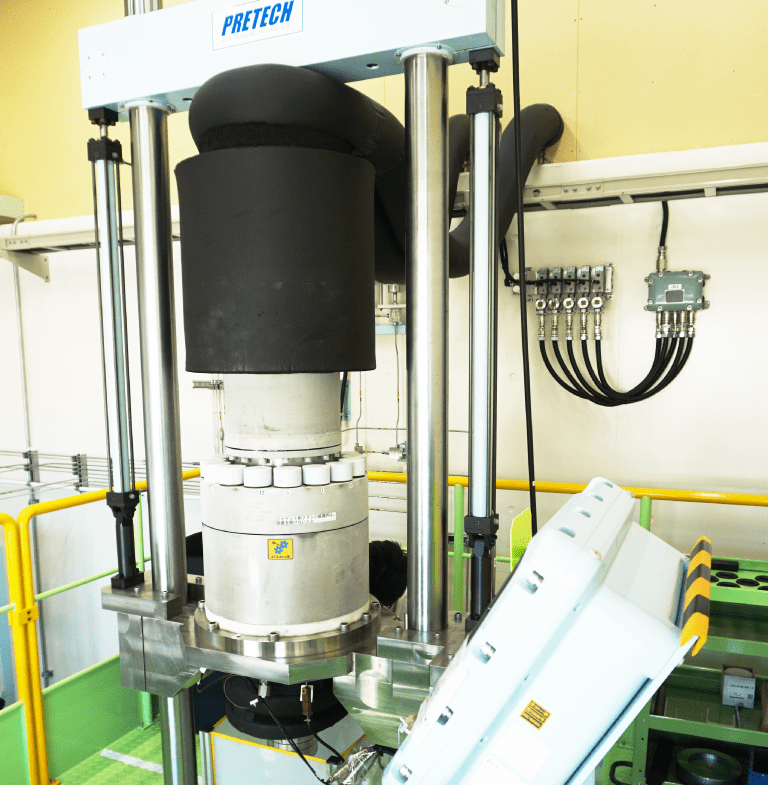

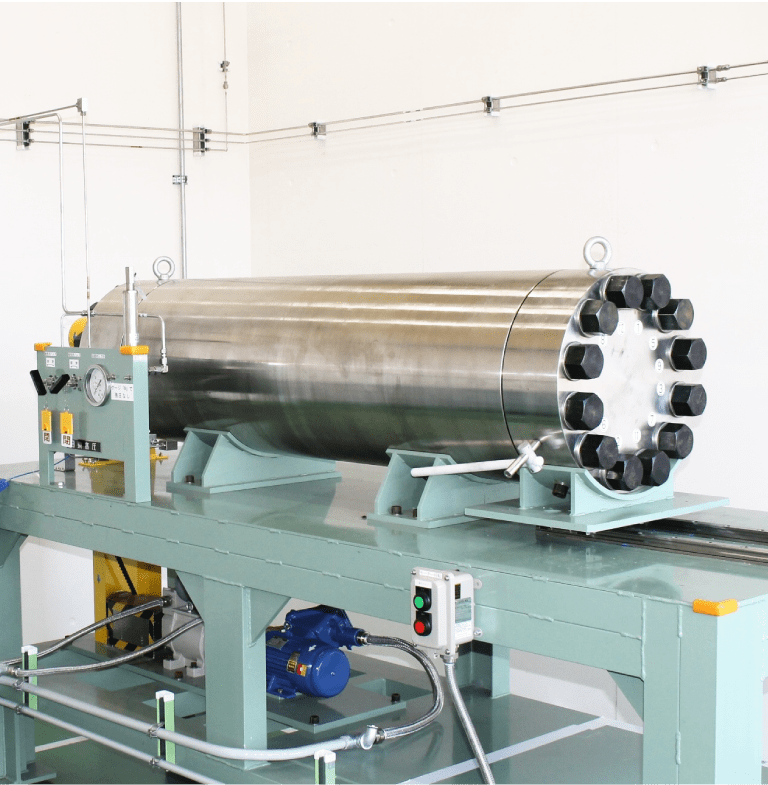

The design of high-pressure hydrogen system parts requires evaluation of tensile properties, fatigue properties, and fatigue crack growth properties in high-pressure hydrogen environments, identical to atmospheric environments.

In 2019, we introduced an axial load type tensile and fatigue testing machine for high-pressure hydrogen environment. In 2021, we developed and started test evaluation of a rotary bending fatigue testing machine in a 90 MPa high-pressure hydrogen gas environment for the first time in the world.

Servo press line for developing next-generation forging

As automobiles become more compact and their mechanisms evolve due to electrification, there is a strong demand for components that make these vehicles compact and lightweight, as well as needing to be highly functional in order to integrate them.

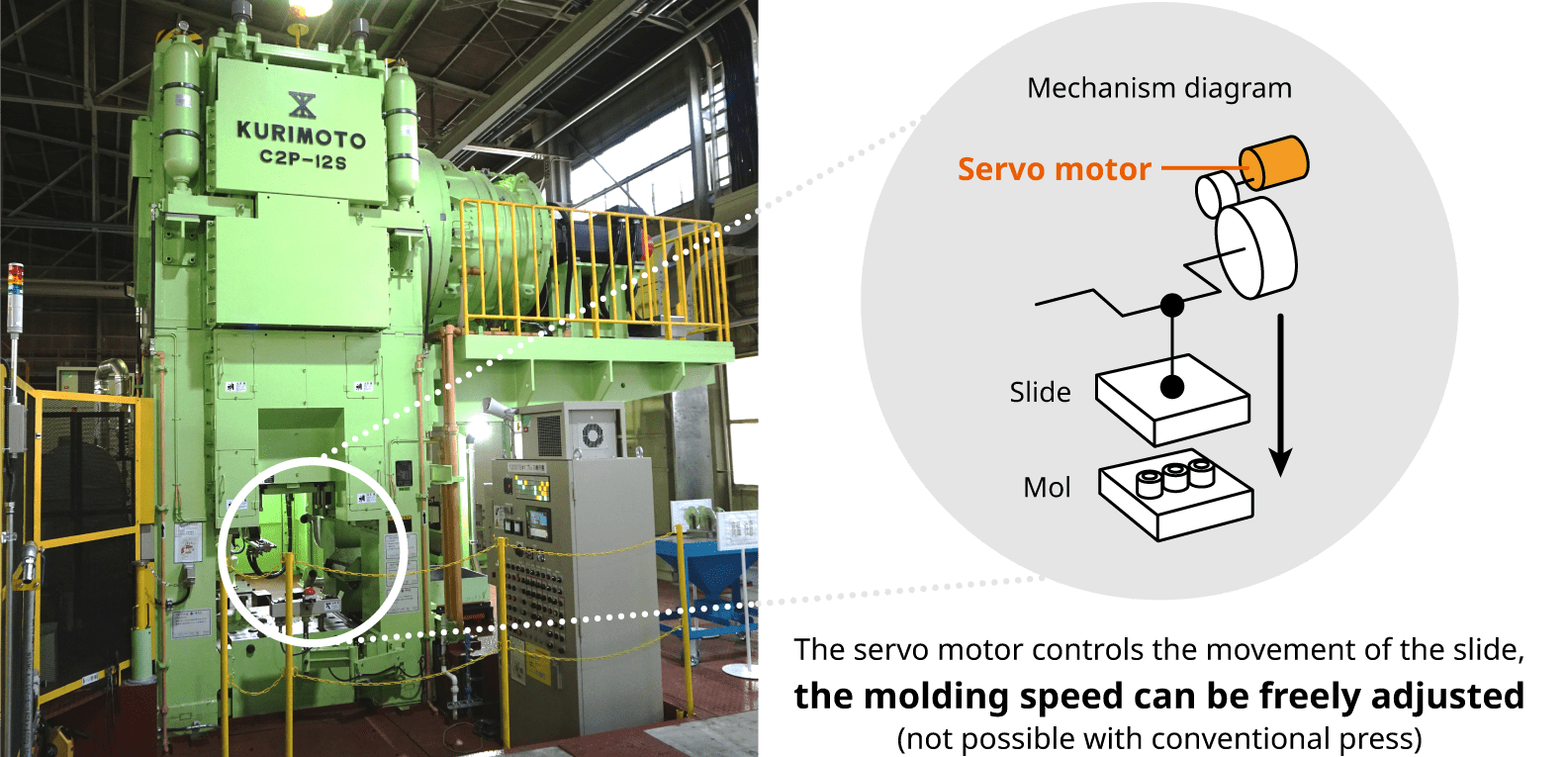

In response to the need for higher functionality of parts for next-generation vehicles, we have introduced a servo press line for forging, which enables the development of innovative methods. Servo press is a technology that can cope with complex shapes that cannot be dealt with conventional hot forging by freely changing the molding speed (figure below). This is the first time that a servo-type press incorporates a double-acting molding mechanism in a forging manufacturer in Japan. New products and techniques leveraging these advantages to the maximum will be developed, accelerating more advanced forging methods.

Equipment configuration: 1200t servo press for forging, high frequency furnace, auxiliary equipment

Servo press mechanism

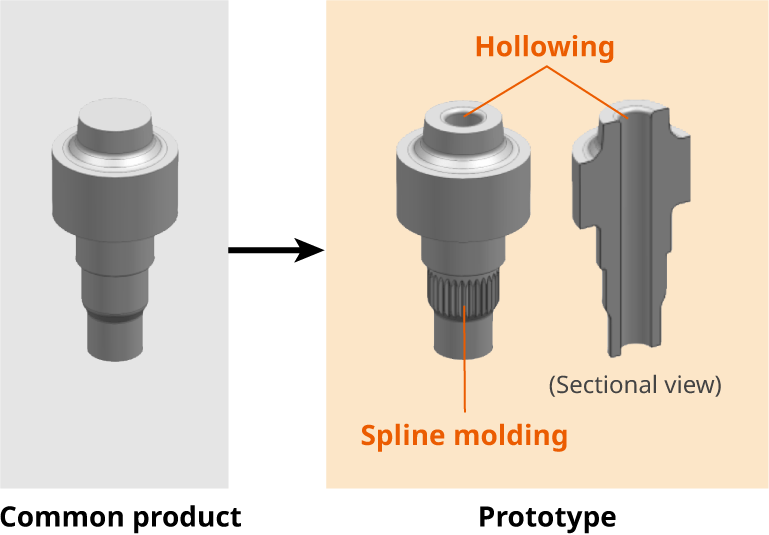

Research example