Environment

Climate Change Initiatives

Basic approach

Aichi Steel emits CO2 both directly and indirectly through the manufacturing processes of its various products, such as heating of steel materials, and melting of steel scrap, which is the raw material of its main product, specialty steel. For this reason, our response to climate change is a serious management issue from the perspectives of risks and opportunities. We are accelerating our efforts to decarbonize with the goal of achieving carbon neutrality as early as 2050. As a resource circulation-based company that uses steel scrap as a raw material in manufacturing, we will utilize our strengths, which have contributed to sustainable manufacturing through materials and parts, to help realize a decarbonized society. To this end, we will also continue to develop and provide products and services that contribute to reduced CO2 emissions across the entire supply chain.

Endorsement of TCFD recommendations and information disclosure

In 2021, we declared our support for the recommendations of the TCFD (Task Force on Climate-related Financial Disclosures.)We have been analyzing various scenarios based on the impacts, and associated risks and opportunities, that climate change may have on our business, and have considered how to reflect the results in management strategy to achieve sustainable growth. We detail our climate-related initiatives here in line with the framework (governance, strategy, risk management, and metrics and targets) recommended by the TCFD.

From FY2024, we established a Sustainability Promotion Department within the Corporate Planning Division to plan and drive company-wide responses to sustainability issues. The department is raising the level of various climate-related initiatives (expanding adoption of renewable energy, acquiring EPDs (Environmental Product Declarations), exploring steel production using non-fossil fuel certificates, utilizing hydrogen gas combustion etc.)

Governance

We have identified climate change as a priority issue (materiality) for management, and are setting KPIs and working to accomplish our targets. As the organization responsible for considering important business management-related matters, the Top Management Meeting and the Environmental Working Group discuss and consider response policies, business strategies, and the status of initiatives related to risks and opportunities that can severely impact business management, such as climate change. The Board of Directors performs its supervisory function by receiving subsequent reports and considering matters that are particularly important.

Risk management

We follow the process on the right to identify, evaluate, and supervise all risk management. We also discuss and report climate change-related risks in the Environmental Working Group and Top Management Meeting to clarify impacts and our responses.

Main agenda items in FY2024

| Meetings | Main agenda items |

|---|---|

| Board of Directors |

|

| Top Management Meeting |

|

| Environmental Working Group |

|

Organization chart

Risk management process

Strategy

While referencing reports of the International Energy Agency (IEA) and the Intergovernmental Panel on Climate Change (IPCC), we developed two scenarios (1.5°C scenario and 4°C scenario) of what society would look like in 2030 assuming a global average temperature rise of 1.5°C and 4°C by the end of this century (compared to pre-industrial levels), and analyzed the risks and opportunities.

Analysis results by scenario

| Scenarios | Analysis results | Our response to scenario |

|---|---|---|

| 1.5°C |

|

|

| 4°C |

|

|

Main risks and opportunities, and response policies (excerpt)

| Scenarios | Climate-related matters | Impact on Aichi Steel | Response policies | |

|---|---|---|---|---|

| 1.5°C | Major transition in the automotive industry

|

Medium |

|

|

|

High |

|

|

||

| Increased demand for decarbonization in society · Demand for electric furnace steel, etc. |

Medium |

|

|

|

Adoption of carbon pricing

|

High |

|

|

|

| Restricted supply of raw materials and other resources |

Medium |

|

|

|

| 4°C | Natural disasters

|

Medium |

|

|

- [Definition of impact]

- High: Risks/opportunities with the potential to impact revenue by billions of yen or more

- Medium: Risks/opportunities with the potential to impact revenue by hundreds of millions of yen

- Based on current company assumptions. Subject to change in the future.

Indicators and targets

We are contributing to the realization of a decarbonized society, with the goal of reducing CO2 emissions from our business operations by 50% by FY2030 compared to FY2013 levels, and achieving carbon neutrality by FY2050. As well as promoting technological development in production processes and implementing energy-saving activities with full employee participation, we are taking active steps to reduce CO2 emissions, such as introducing more solar power generation and other non-fossil energy sources. In FY2024, we achieved steady results, with a 25.4% reduction compared with FY2013 on a non-consolidated basis and a 26.5% reduction on a consolidated basis.

Non-consolidated

Consolidated

Roadmap to carbon neutrality by 2050

We have formulated and are systematically implementing a roadmap for achieving our targets. We have also detailed plant-specific roadmaps, and we are systematically conducting activities focused on (1) deepening and pursuing energy savings, (2) utilizing renewable energy, and (3) developing and adopting decarbonization technologies. In FY2024, we drew up a roadmap for our group's eight domestic subsidiaries to reduce GHG emissions. Going forward, we will engage in GHG reduction activities in our group, both domestically and internationally.

Specific initiatives

Utilization of renewable energy

The large amounts of electricity used in Aichi Steel's specialty steel manufacturing processes have made it essential to shift to electricity derived from renewable energy. Therefore, in addition to thorough efforts to conserve energy and improve efficiency, we are actively promoting adoption of such electricity. In June 2025, Higashiura Plant launched operation of solar power generation using on-site PPA, which is expected to reduce annual CO2 emissions by more than 700 tons at our three plants (Higashiura, Seki, and Gifu). In July 2025, we began procuring renewable energy (approximately 100 million kwh/year) through off-site PPAs, which is expected to reduce approximately 43 thousand tons/year of CO2. Our plan is to continue to expand stably procurable renewable energy sources from a long-term perspective.

In addition to electricity, we are considering the conversion of energy used at our plants, such as city gas, to hydrogen through our participation in the Hydrogen Utilization Study Group in Chubu. Initially, at Kariya Plant, we have carried out modification work on the steel material heat treatment furnace to enable hydrogen combustion, and have started verification trials of hydrogen combustion technology. With the goal of developing hydrogen-based steel heat treatment technology, we will continue to conduct verification for hydrogen utilization, including hydrogen combustion trials and knowledge collection. As a member of the Hydrogen Utilization Study Group in Chubu, we also aim to utilize the knowledge gained from these verifications to expand the use of hydrogen at other plants.

CO2 emissions by scope

[Scope 1, 2]

| CO2 emissions (1,000 t-CO2) | |||||

|---|---|---|---|---|---|

| FY2013 (base year) | FY2022 | FY2023 | FY2024 | ||

| Non-consolidated | Scope 1, Scope 2 | 257, 540 | 222, 394 | 224, 410 | 223, 372 |

| Total amount | 797 | 616 | 634 | 595 | |

| Affiliated companies | Scope1, Scope2 | 23, 110 | N/A | 23, 72 | 22, 67 |

| Total amount | 133 | N/A | 95 | 89 | |

| Consolidated total | 931 | N/A | 729 | 684 | |

- Calculation method:

- Calculated based on “Standard Calorific Values and Carbon Emission Factors for Energy Resources” (Agency for Natural Resources and Energy) under the Act on Promotion of Global Warming Countermeasures (MOE), and the annual emission factors of contracted electricity providers

[Scope 3] *Non-consolidated

| CO2 emissions (1,000 t-CO2) | Calculation methods | |||

|---|---|---|---|---|

| FY2022 | FY2023 | FY2024 | ||

| 1. Purchased products and services | 793 | 901 | 845 | Calculated by multiplying purchased quantities (weight or monetary value) of raw materials and supplies by emission intensity |

| 2. Capital assets | 37 | 50 | 46 | Calculated by multiplying capital expenditure by emission intensity |

| 3. Fuel and energy related activities not included in Scope 1 and 2 | 110 | 122 | 120 | Calculated by multiplying consumption of purchased electricity and fuel by their emission intensities |

| 4. Transportation and distribution (upstream) | 37 | 36 | 37 | Calculated by multiplying transportation distance reported under the Energy Conservation Act, and transportation mode and distance of Category 1 purchased goods, by emission intensity |

| 5. Waste from operations | 10 | 9 | 9 | Calculated by multiplying waste amount by emission intensity |

| 6. Business travel | 0 | 0 | 0 | Calculated by multiplying the payment amount by mode of transportation by emission intensity |

| 7. Employee commuting | 3 | 3 | 3 | Calculated by multiplying reimbursement amount by mode of transportation by emission intensity |

| 8. Leased assets (upstream) | 0 | 0 | Calculated by multiplying energy consumption of leased assets by emission intensity | |

| 9. Transportation and distribution (downstream) | – | – | – | Excluded - unspecified |

| 10. Machining of sold products | 357 | 327 | Related to machining of intermediate products. Calculated by multiplying sales volume by emission intensity | |

| 11. Use of sold products | – | – | – | Excluded - products do not emit CO2 directly during use |

| 12. Disposal of sold products | 9 | 9 | Calculated by multiplying weight of waste and recyclable products by emission intensity | |

| 13. Leased assets (downstream) | 0 | 0 | 0 | Calculated by multiplying energy consumption of leased assets rented to other companies by emission intensity |

| 14. Franchises | 0 | 0 | 0 | No franchisees |

| 15. Investments | – | – | – | Excluded from calculation - not an investment company |

| Total | 990 | 1,486 | 1,396 | |

- Figures in the above table are rounded to the nearest thousand tons, and 0 means less than 500 tons.

- Emission intensity:

- “Emission Intensity Database for Calculating Greenhouse Gas Emissions of Organizations Throughout the Supply Chain (Ver. 3.5))” (April 2025, MOE) and “LCI Database IDEA version 3.5”

(Advanced LCA Research Group, Research Institute of Science for Safety and Sustainability, National Institute of Advanced Industrial Science and Technology(AIST))

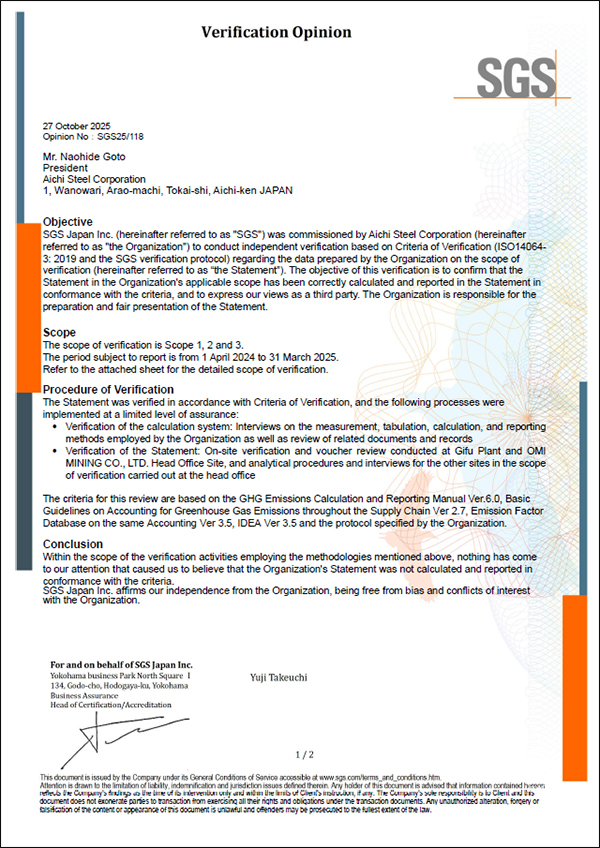

We have undergone independent third-party verification by SGS Japan Inc. to improve the reliability of our greenhouse gas emissions.

https://www.aichi-steel.co.jp/sustainability/esg/verification@en.pdf

Collaboration with society

To help drive social change and achieve carbon neutrality by 2050, we are participating in various initiatives and obtaining relevant certifications. Through these activities, we seek to expand the use of products and services that contribute to decarbonization, and to maintain and strengthen competitiveness in the specialty steel industry in Japan.

Acquisition of SuMPO EPD label

In April 2025, we acquired SuMPO EPD environmental product certification for our specialty steel bars and formed stainless steel products. An EPD is a certification system that objectively evaluates and reports the environmental impact of products, providing quantitative environmental information on the entire product life cycle, from resource extraction, manufacturing, and distribution to use and disposal or recycling. Obtaining this certification will enable us to disclose objective and transparent environmental information, supporting our customers' efforts to address environmental issues.

Start of hydrogen combustion verification trials at Kariya Plant

In July 2024, we started hydrogen combustion technology verification trials at Kariya Plant as part of our efforts to carbon neutrality. In cooperation with Toho Gas Group and others, we modified our steel heat treatment furnace equipment that uses city gas to be compatible with hydrogen combustion. Our goal is to develop heat treatment technology using hydrogen, and we plan to use the knowledge gained for rollout to other plants.

Basic agreement on hydrogen utilization signed with the Central Japan Hydrogen and Ammonia Association

In October 2024, we signed a basic agreement to work toward carbon neutrality with the Central Japan Hydrogen and Ammonia Association, established by Aichi Prefecture, and 20 supporting companies. The aim is to establish a nationwide, pioneering large-scale hydrogen and ammonia supply chain, to be promoted regionally through public-private partnerships. By advancing the use of clean energy, including hydrogen, we will help realize a sustainable global environment.

For more information about the Central Japan Hydrogen and Ammonia Association, please visit

Participation in the Aichi Environmental Innovation Consortium

In January 2025, we joined the Aichi Environmental Innovation Consortium, which is made up of 51 organizations including companies, universities, financial institutions, and government agencies. Based in Aichi, the consortium aims to create and implement environmental innovations to tackle challenges such as achieving carbon neutrality, transitioning to a circular economy, and realizing nature-positive outcomes. Aiming to achieve carbon neutrality as early as 2050, we will apply our knowledge gained from energy-saving activities, technology development, renewable energy use, and biodiversity conservation to help build a sustainable society.

For more information about the Aichi Environmental Innovation Consortium, please visit

Environmental Management

Basic approach

To achieve the Vision 2030 management mission of contributing to society as the “most environmentally friendly steelmaker,” Aichi Steel formulated the Aichi 2025 Environmental Action Plan to chart a course of action through to 2025. It defines targets that should be accomplished by 2025, and we are currently working to achieve these targets, focusing on the three pillars: eco-energy, eco-production, and eco-management.

| Initiatives | Targets for 2025 | |

|---|---|---|

| Eco-energy |

|

CO2 emissions: 30% reduction (compared to FY2013) |

| Eco-production |

|

Amount of landfill waste: 2,400 t/year or less |

| Eco-management |

|

Nakashinden environmental indicator species: 27 species attracted |

Promotion structure

Aichi Steel is working to implement environmental management through effective employment of the PDCA cycle mainly through the Environmental Working Group, which operates under the supervision of its Board of Directors with the president as chairperson. The Environmental Working Group is in charge of executing strategy, establishing targets, and checking progress in accordance with company policies and the Aichi Environmental Action Plan. Seven subcommittees have been established under the Environmental Working Group with clear areas of responsibility to promote efficient and targeted activities based on specialized perspectives. In addition, the Aichi Steel Group Environmental Committee was established to share information and successful case studies to promote Groupwide activities.

Organization chart

| Subcommittees | Initiatives |

|---|---|

| Environmental Conservation |

|

| CN Promotion |

|

| Production Energy Conservation |

|

| Process Reform |

|

| Resource Circulation |

|

| Eco-products |

|

| Awareness and Publicity |

|

Eco-energy

Approximately 90% of our CO2 emissions come from electricity and city gas used to melt steel scrap and heat steel materials. Based on the roadmap formulated toward achieving carbon neutrality by 2050, we are promoting the reduction of energy consumption through efforts to deepen the energy-saving technologies that we have cultivated, the elimination of waste in our daily operations, and drastic improvements in manufacturing processes. In FY2024, we conducted 129 energy-saving activities.

Regarding the introduction of non-fossil energy, we have already introduced solar power generation through on-site PPAs at Seki Plant and Gifu Plant. In FY2025, we will install a new solar power generation facility at the Higashiura Plant, and systematically expand the introduction of non-fossil energy by also utilizing biomass power generation through offsite PPAs.

Breakdown of CO2 emissions in FY2024

(Scope 1 + Scope 2 emissions from Aichi Steel on non-consolidated basis)

Resource Circulation

Eco-production

Aichi Steel is a resource circulation-based company that both recirculates steel resources and achieves economic value, by recycling steel scrap generated from the dismantling of automobiles and infrastructure into high-quality specialty steel products, automotive components, and other products. We aim to transition to a circular economy by further accelerating our efforts to reuse products and parts and recycle waste and raw materials while reducing resource input and consumption through the efficient use of resources and energy.

Efforts to increase by-product recycling rates

We have strengthened our recycling of by-products that were previously sent to landfills, maintaining a recycling rate in the upper 90% range. Slag generated in electric furnaces is primarily used as roadbed material for roads, while electric furnace dust is sent to recycling companies for processing to recover valuable metals. Additionally, waste brick used in steelmaking and refining is sorted and crushed, then reused as slag-forming material in electric furnaces. At present, we are focusing on developing technology to recycle slag-based by-products, which are difficult to process, as slag-forming material, with the aim of reducing the amount of landfill to 2,000 tons by 2030 and zero by 2050.

Trends in byproducts sent to landfill and byproduct recycling rate

Amount of industrial waste discharged from products using plastic

Initiatives for a circular economy

We are a member of Circular Core, an association for promoting the sound development of a circular economy, creating new value, and advancing sustainable manufacturing that is environmentally friendly, through collaboration across automotive materials, components, and the entire supply chain. The association actively conducts market research on the circular economy covering automotive materials, components, and the entire supply chain, researches, develops hypothesis and validates the latest technological trends and business practices, and engages in exchanges and cooperation with relevant domestic and international organizations.

Biodiversity

Eco-management

As a resource circulation-based company, we carry out manufacturing that achieves both the circulation of iron resources and economic value. In our business activities, we constantly benefit from the gifts of biodiversity, including natural resources and water. On the other hand, our CO2 emissions and wastewater from melting scrap and heating steel materials impact biodiversity.

We are deeply aware of the importance of biodiversity, which is being continuously lost. Based on the following policies, we contribute to a sustainable society by conserving biodiversity and developing businesses that protect and utilize nature.

Aichi Steel Group's Biodiversity Policy

1. Protection and restoration of ecosystem

- We assess the impact of our business activities on nature and take appropriate protective measures.

- We explore environmental conservation measures that take advantage of nature’s gifts in order to minimize our impact.

- We contribute to the restoration of nature by leveraging our proprietary technologies derived from our special steel manufacturing expertise.

2. Sustainable use

- We promote sustainable methods and use in the areas of “climate change, water, and resources,” which impact nature.

3. Collaboration with local communities

- We work together with local communities to conserve and restore biodiversity and guide nature toward regeneration.

Through these efforts, we are contributing to achieving a “world in harmony with nature (nature positive)” by 2050.

Biodiversity conservation initiatives

We endorse the Biodiversity Declaration and Action Guidelines of the Japan Business Federation (Keidanren) and are engaged in conservation activities. We also contribute to the revitalization of nature as a participant in the 30 by 30 Alliance, established by government agencies, companies, and NPOs.

Since FY2012, we have been promoting the Forest Habitat Creation for Beetles project in the Nakashinden Greenbelt adjacent to Chita Plant, maintaining an environment that attracts 50 indicator species. The site, which forms part of Chita Peninsular Greenbelt, a collaboration among 11 organizations including Aichi Steel and other companies, government agencies, students, experts, and NPOs, was certified in FY2023 by the Ministry of the Environment as a Nature Symbiosis Site.

In 2024, we planted 6,000 trees while zoning*, and hosted a tree-planting ceremony attended by the Mayor of Tokai. In November, we were recognized as an Aichi Biodiversity Excellence Certified Company. Furthermore, we have been conducting forest cultivation activities in Nagano Prefecture since 2006, and in 2019, we signed a Forest Adoption Agreement with Otaki Village, the water source for our business operations. Employees and their families regularly engage in conservation activities, working together with the local community to nurture a richer forest.

- The process of determining optimal plant placement

Disclosures based on TNFD (Taskforce on Nature-related Financial Disclosures)

The impact of resources such as biodiversity and water varies by region, and so we feel we need to adopt a region-specific perspective. We will proceed with information disclosure based on the recommendations of the TNFD. We have begun assessing the impact of our business activities on nature through a process in line with the LEAP approach advocated by the TNFD. The aim is to publish this by the end of FY2025.

LEAP/TNFD explanation

The LEAP Approach

- Developed by TNFD as an integrated approach for assessing nature-related issues, including points of contact with nature, dependencies on nature, and impacts, risks, and opportunities related to nature.

- In the LEAP approach, following scoping, an organization progresses through the steps of Locate, Evaluate, Assess, and Prepare to build readiness for TNFD disclosures.

LEAP approach diagram