Environment

Environmental Management

To achieve the Vision 2030 management guideline of "Contribution to a sustainable global environment," Aichi Steel formulated the Aichi 2025 Environmental Action Plan to chart a course of action through to 2025. We defined targets to accomplish by 2025, and we are currently working to achieve these targets, focusing on the three pillars: eco-energy, eco-production, and eco-management.

| Eco-energy |

|

|---|---|

| Eco-production |

|

| Eco-management |

|

Conceptual diagram of environmental policies

Promotion Structures

Aichi Steel is working to implement environmental management through effective employment of the PDCA cycle mainly through the Environmental Working Group, which operates under the supervision of its Board of Directors with the president as chairperson. The Environmental Working Group is in charge of executing strategy, establishing targets, and checking progress in accordance with company policies and the Aichi Environmental Action Plan. Six subcommittees have been established under the Environmental Working Group with clear areas of responsibility to promote efficient and targeted activities based on specialized perspectives. In addition, the Aichi Steel Group Environmental Committee was established to share information and successful case studies to promote Groupwide activities.

| Subcommittees | Roles |

|---|---|

| CN Planning |

|

| CN Technology Innovation |

|

| CN Energy Conservation |

|

| CN Process Reform |

|

| Environmental Conservation |

|

| Eco-products |

|

Eco-energy

Approximately 90% of Aichi Steel's CO2 emissions come from the use of electricity to melt steel scrap in the steel making process, and from the use of city gas to heat steel materials. Based on the roadmap formulated toward achieving carbon neutrality by 2050, we are promoting the reduction of energy consumption through efforts to deepen the energy-saving technologies that we have cultivated, the elimination of waste in our daily operations, and drastic improvements in manufacturing processes. In fiscal 2022, in addition to ongoing energy-saving activities and the introduction of solar power generation facilities, we began exploring the use of future decarbonization technologies such as hydrogen and Carbon Capture, Utilization, and Storage (CCUS).

Breakdown of CO2 emissions in FY2022

(Scope 1 + Scope 2 emissions from Aichi Steel on a non-consolidated basis)

Pursuit of eco-energy

Aichi Steel's energy conservation activities are being promoted through working groups that engage in activities from three perspectives: thorough horizontal deployment of effective measures to maximize energy efficiency and minimize energy loss in manufacturing processes, visualization of energy consumption by building an IoT infrastructure (visualization of waste), and the fostering of awareness among employees of energy conservation.

(1) Reduction of heat loss by applying low-emissivity coating to steel heating furnaces

We are working to reduce heat loss due to radiated heat by applying low-emissivity coating to steel heating furnaces. After conducting verification using a model facility, we were able to reduce heat loss due to dissipation to less than half that of the conventional method. In the future, we plan to expand the target facilities to include in-house steel heating furnaces to further reduce heat loss. In addition, we are minimizing standby operation loss by improving compressor control and reducing the amount of energy used by improving facilities.

(2) Visualization of energy usage status

We are building a system that enables us to collect and analyze real-time and precise energy usage status by utilizing IoT. In the future, we will link operational data to the system and analyze data on a line-by-line and facility-by-facility basis, thereby enhancing energy management, such as the improvement of energy efficiency and flexible adjustment to demand response.

Adoption of clean energy

Aichi Steel is working to expand the introduction of solar power generation and the adoption of clean energy for the utilization of hydrogen in the future. By purchasing feed-in tariff (FIT) non-fossil certificates*1 with tracking in fiscal 2021, the power used at four plants (Gifu Plant, Seki Plant, Higashiura Plant, and Kariya Plant) was virtually converted to renewable energy. In fiscal 2022, solar power generation facilities were installed at two plants (Seki Plant and Gifu Plant), which began operation in fiscal 2023. In anticipation of future hydrogen utilization, we have also introduced gas burners that can use both hydrogen and city gas as fuel. Going forward, we will develop technologies and conduct verification trials.

Achievement of carbon neutrality by plant

- Certificates of the environmentally friendly value of electricity generated by non-fossil power sources (power sources that generate electricity without using fossil fuels such as coal and oil), which are subject to the FIT program established to promote the spread of renewable energy

- City gas produced using carbon neutral LNG, in which CO2 generated in the processes from mining to the combustion of natural gas is offset by CO2 credits (carbon offsetting)

Eco-production

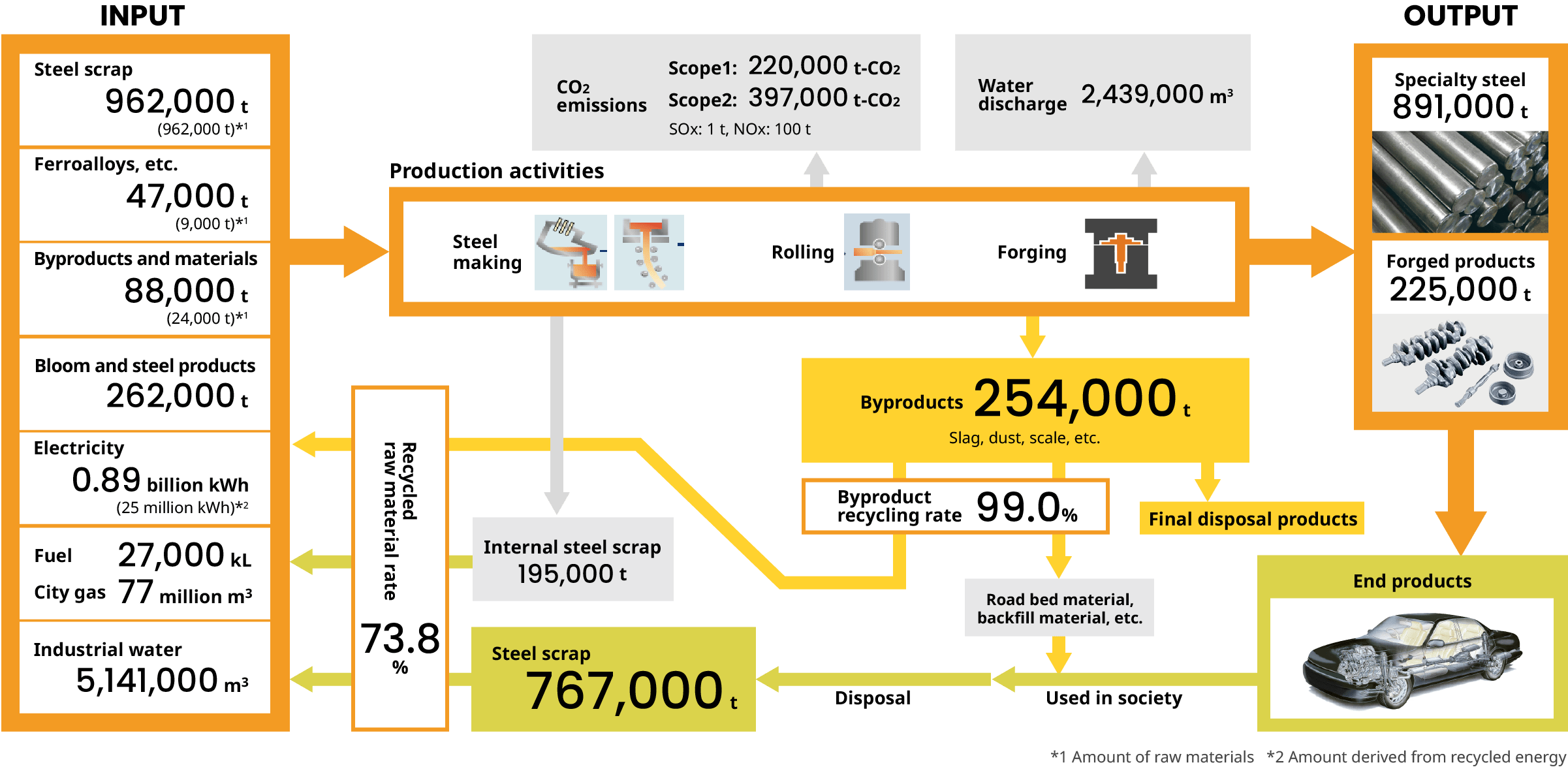

Aichi Steel is a resource-recycling company that realizes both the recycling of steel resources and economic value by turning steel scrap generated from the dismantling of automobiles and infrastructure into high-quality specialty steel products, automotive components, and other products. We aim to transition to a circular economy by further accelerating our efforts to reuse products and parts and recycle waste and raw materials while reducing resource input and consumption through the efficient use of resources and energy.

Pursuit of resource circulation

Aichi Steel is conducting 4R activities (Reduce, Reuse, Recycle, Renewable) to effectively use limited resources and energy without waste.

| 4Rs | Examples of our initiatives | |

|---|---|---|

| Reduce |

|

|

| Reuse |

|

|

| Recycle |

|

|

| Renewable |

|

|

Eco-management

Based on the belief that symbiosis with local communities and nature is necessary for its sustainable growth, Aichi Steel is working on local environmental conservation activities in collaboration with related organizations.

Amount of industrial waste discharged from products using plastic

Biodiversity conservation efforts

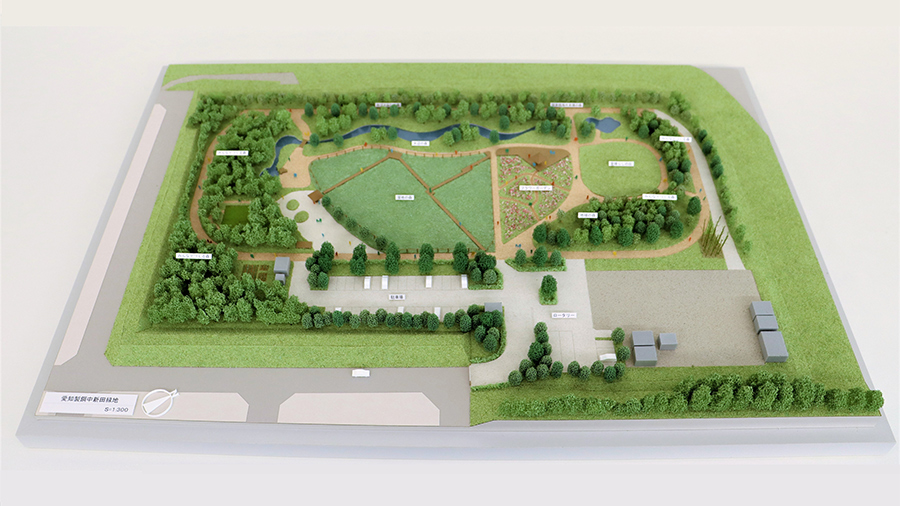

As part of its conservation activities, Aichi Steel has been working since fiscal 2012 to create an environment where 50 indicator species that have traditionally inhabited the area can gather, under the slogan of "creating a forest where beetles live" in the Nakashinden green space, which covers an area of approximately 20,000 m² adjacent to the Chita Plant. In addition to forestation through tree planting and biotope maintenance, we use this initiative to foster environmental awareness through employee volunteer activities such as rice planting and harvesting to interact with nature. The indicator species are regularly monitored to provide reference for future maintenance. Currently, 19 indicator species have been identified, and a variety of organisms have started settling in the area. In 2023, we received the 3rd ABINC Award Special Prize presented by the Association for Business Innovation in Harmony with Nature and Community (ABINC)* in recognition of our efforts as an outstanding example of corporate activities for biodiversity conservation.

- An association established to promote symbiosis between nature and people in corporate activities

Forestation for water sources

Aichi Steel uses water from the Aichi waterworks, which has its source in Otaki Village, Nagano Prefecture, for the operation. As part of our activities to protect this water source, we have been engaging in water source forest cultivation activities since 2006. In 2019, we concluded a “foster parent of forest” agreement with Otaki Village. We have designated approximately 12 hectares of forest as FOREST of AICHI STEEL GROUP, where our employees and their families regularly conduct thinning and pruning work in cooperation with Otaki Village and local residents to promote the creation of a rich forest.

Collaborative activities with related organizations

Aichi Steel also focuses on environmental conservation activities in collaboration with related organizations. One of these organizations is the Chita Peninsula Ecosystem Network Council, in which local governments, universities, NPOs and other private organizations, and companies participate to promote activities to form an ecosystem network through the vision for the nature in the region and efforts to achieve it. We conduct collaborative activities and information sharing with the aim of having corporate green spaces owned by participating companies certified as Natural Symbiosis Sites* promoted by the Ministry of the Environment. Through these efforts, we will actively work toward the realization of "nature positivity," which will halt the loss of biodiversity and restore nature.

- Sites recognized by the Ministry of the Environment as areas where biodiversity is being conserved through private sector efforts and other measures